UpTime’s Wireless Condition Monitoring Technology

Build a successful maintenance program that reduces costs and downtime while building a stronger reliability culture in your facility.

What Previous Clients Are Saying About Our Wireless Condition Monitoring Sensors & Software

PROUDLY PARTNERING WITH

What Sets Us Apart from Other Condition Monitoring Companies

We deliver proven reliability strategies and scalable solutions that stand out in the industry.

ISO 9001 & 27001-Certified

We ensure our products meet the highest standards for data security, quality, and reliability, giving you confidence in every sensor, insight, and workflow.

20 Years of Experience

For over two decades, UpTime has been delivering high-quality, scalable condition monitoring solutions.

Best in Large-Scale Installations

We delivered the world’s largest single-site wireless condition monitoring (CM) installation, demonstrating our ability to execute complex, high-impact projects proficiently.

Expert Lead Reliability Strategies

With in-house experts in reliability, condition monitoring, and maintenance strategy, you get direct access to proven guidance. Their hands-on support helps you build a tailored, effective reliability program built for long-term success.

Ground-Level Buy-In

We provide accurate CM assessments that showcase rapid ROI and secure buy-in from all levels of your organization.

Confident, clear, and in control

Equip your rotating machinery with UpTime Solutions’ wireless condition monitoring system to catch issues before they cause breakdowns. Our prescriptive, real-time diagnostics deliver accurate, actionable intelligence—keeping your operations relentlessly moving forward.

Our Wireless Condition Monitoring Sensors & Software

MistLX

Compact, rugged wireless sensor for monitoring ultrasound, vibration, and temperature.

- Small form factor for versatile mounting options

- Bluetooth connectivity to UpCastCM, UpTime’s cloud platform

- Designed for scalable deployments and large-scale rollouts

- IP69-rated for maximum protection

- Optional stainless steel housing for wet, high-moisture, or washdown environments

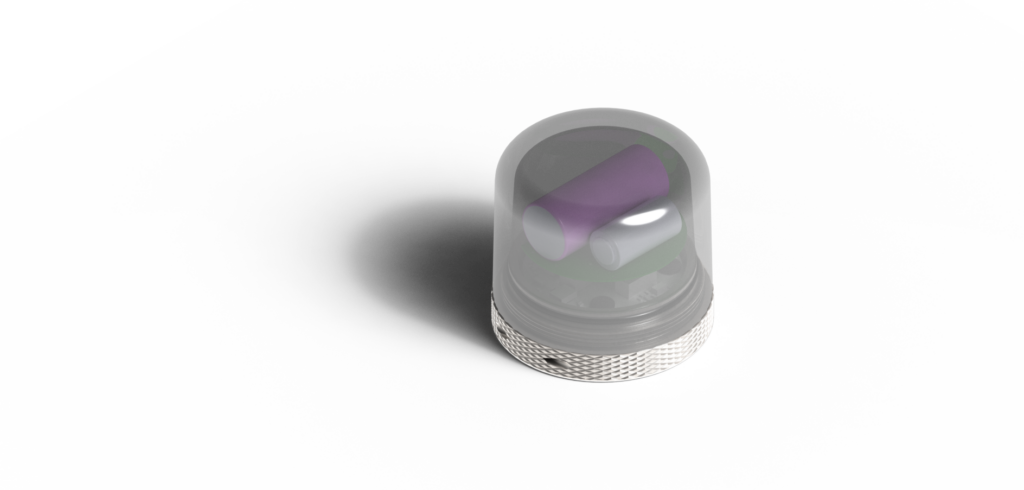

MistEX

High-performance wireless sensor with extended battery life, offering the same sensing capabilities as MistLX.

- Up to 5 years of battery life

- Bluetooth connectivity to UpCastCM, UpTime’s cloud platform

- Designed for scalable deployments and large-scale rollouts

- IP69-rated for maximum protection

- Optional stainless steel housing for wet, high-moisture, or washdown environments

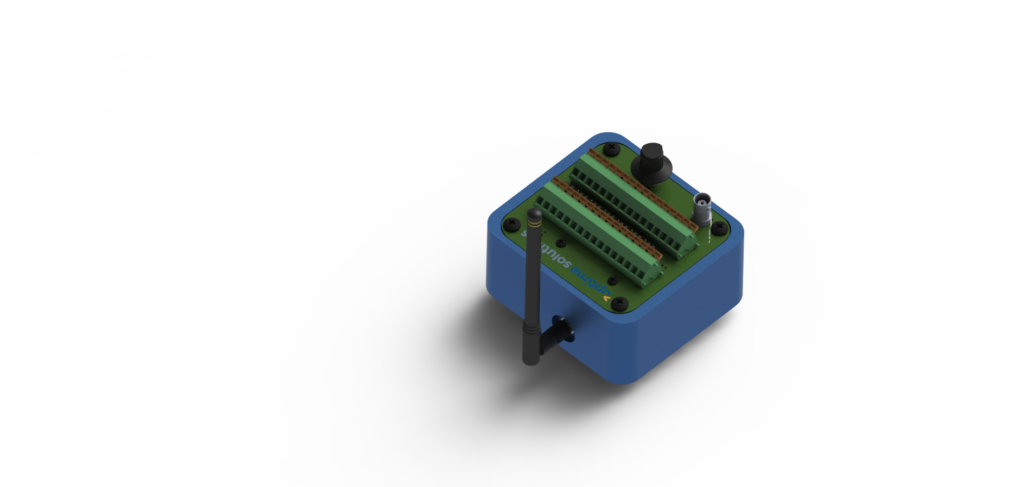

Brick-TS1X

Hybrid wireless sensor that integrates existing wired inputs into UpTime’s platform — without batteries or additional infrastructure.

- Powers and reads up to 15 sensor inputs

- Converts junction boxes or accelerometers into wireless data hubs

- Long-range 900 MHz wireless connectivity with no battery swaps

- Wirelessly transmits data from up to 7 accelerometers and 7 process channels (+tach)

UpCast CM

UpCastCM connects all UpTime sensors to a secure, cloud-based platform, giving real-time visibility into vibration, ultrasound, and temperature data. With smart analytics and prescriptive diagnostics, it turns sensor readings into actionable insights—helping your team prevent failures, prioritize maintenance, and maximize uptime across single or multiple sites.

An Expert-Driven Approach to Condition Monitoring Analysis

Installation & Deployment

UpTime Solutions makes large-scale wireless CM deployments seamless and reliable. Our experienced implementation team ensures that every installation — from single-site to multi-site rollouts — is executed efficiently, accurately, and with minimal disruption to operations.

- Hands-on approach: Unlike providers who simply ship sensors, our team manages installation, setup, and onboarding to ensure your system works perfectly from day one.

- Smart software integration: Our platform is designed to scale with your data, becoming faster and more capable as your network grows.

- Proven scalability and support: Our team continues to assist you after installation, ensuring smooth expansion across multiple sites, training your staff, and providing ongoing optimization so your system delivers maximum value.

Revolutionary 3-in-1 Sensors

Monitor your assets with the industry’s only all-in-one sensors for ultrasound, vibration, and temperature. While other companies require multiple sensors for different machines, UpTime provides a single solution that covers it all by:

- Simplifying deployment

- Reducing maintenance

- Giving you complete visibility into your equipment’s health

CAT-Certified Analysts

Our team of veteran analysts brings over 20 years of experience in vibration, ultrasound, and temperature monitoring. They serve as your dedicated experts, setting accurate alarm thresholds and continuously monitoring your data to provide actionable insights every day.

- Real-time monitoring of asset health

- Alarm threshold configuration tailored to your equipment

- Immediate escalation of time-critical issues

- Ongoing support from tenured professionals who understand your operations

Prescriptive Diagnostics

UpTime’s analysts don’t just provide alerts—they deliver actionable intelligence. With prescriptive diagnostics, your team receives clear guidance on what to do, when, and how.

- Fault prioritization: Quickly understand which issues need immediate attention

- Detailed analysis: Receive specifics on the fault, its potential causes, and impact

- Maintenance recommendations: Actionable steps for mitigation, delivered through a user-friendly hub and custom reports

- Continuous updates: Real-time insights ensure your team is always informed and prepared

Wireless Condition Monitoring FAQs

Everything you need to know about our services. Can’t find the answer you’re looking for? Contact our team.

Do You Offer a Trial or a Pilot Program?

Yes. If you’ve been frustrated by self-install sensor kits, unclear ROI claims, or pressure to scale before you’re ready, UpNow™ was designed for you.

What’s Included in our UpNow™ Pilot:

- MistLX™ Sensors – IP69-rated, stainless steel, and built to withstand a washdown environment

- 3-in-1 Monitoring – ultrasonic, vibration, and temperature data in a single sensor

- Certified Expert Installation – no DIY required

- 1-on-1 Consultation – direct access to maintenance and reliability experts

- Continuous Monitoring & Insights – actionable recommendations without confusing dashboards

- Access to UpTime360 & UpCast™ Platforms – real-time visibility and analytics

Experience a pilot program that delivers real results, clear insights, and hassle-free installation — so you can see the value before committing to a full rollout.

How Does UpTime’s Condition Monitoring Solution Scale With Organizations as They Grow?

UpTime’s wireless condition monitoring solution is designed for both rapid deployment and long-term growth. Our experienced implementation team has successfully scaled programs from single-site pilots to multi-site rollouts covering dozens of facilities nationwide.

With proven expertise in large-scale installations, our approach ensures consistent performance, reliable data collection, and ongoing optimization as your monitoring needs expand. Smart software architecture and cloud-based data management enable the platform to handle increasing volumes of asset data without slowing. At the same time, our analysts provide continuous support to maintain accuracy, insight, and actionable diagnostics across all sites.

How Far in Advance Do Your Sensors Detect Potential Failures?

UpTime’s sensors provide the earliest possible detection of asset failures by combining ultrasound, vibration, and temperature monitoring in a single device.

By capturing changes across the full lifecycle of your assets, our solution gives you a long planning horizon — often providing 6–12+ months of advance notice for scheduled maintenance, maximizing uptime, and reducing unplanned downtime.

How Should Condition Monitoring Data Feed into Maintenance Workflows?

Condition monitoring data should do more than flag potential risks and failures. It should:

- Integrate seamlessly into CMMS/EAM systems

- Drive a shift from reactive to proactive work

- Support better planning for manpower, spares, and lead times

- Enable earlier detection and smarter decisions

If you’re told a bearing will fail in a week and you wait a week to make repairs, that’s still reactive maintenance. The primary goal of CM is to detect issues and failures well before they occur, reducing the likelihood of costly downtime.

How Long Does It Take to Shift from Reactive to Proactive?

The timeline depends on leadership, culture, and engagement — but the shift is achievable, often faster than you might expect. With the right approach, teams can transform in months, not years.

At one Louisiana coal facility, our client eliminated reliance on contractors, empowered internal maintenance teams, and reestablished ownership and discipline — leading to a measurable cultural shift within months.

Progress typically happens in stages: moving from reactive → proactive → refined proactive. Even small, consistent steps add up — turning “good” maintenance into truly great maintenance.

When It Comes to Condition Monitoring, Which Assets Should Be Prioritized?

There are two ways to prioritize condition monitoring:

- Conventional: Focus on assets that present the highest production risk.

- Advanced: Use Risk Priority Numbers (RPNs) to rank assets by failure-mode risk. This calculation considers severity, likelihood, and detectability — helping ensure monitoring is applied where it delivers the most value.

Whether you’re exploring our Pilot Program as a new client or expanding monitoring for a recently added fleet, our support team can guide you in identifying which assets will benefit most from integration into your wireless condition monitoring system.

Gain the clarity you deserve

Protect your line’s bottom line by maximizing the ROI on your capital equipment.

Ready to get every ounce of value from your assets? Let’s talk.