Turning Sensor Data into Action: Making Predictive Maintenance Work for Your Team

Collecting sensor data is easy—acting on it is the challenge. Learn how maintenance teams can turn vibration, temperature, and lubrication data into actionable insights that reduce downtime, improve reliability, and make predictive maintenance work in the real world.

5 Maintenance Mistakes That Are Hurting Your Reliability—and How Predictive Sensors Solve Them

Even the most experienced maintenance teams make costly mistakes—from over-servicing healthy assets to reacting too late to early warning signs. This post breaks down five common maintenance pitfalls and shows how predictive maintenance with condition monitoring sensors helps teams reduce downtime, cut costs, and improve equipment reliability.

Preventive Maintenance vs Predictive Maintenance: Are You Wasting Money?

Are you spending too much on routine maintenance? Discover how relying solely on preventive maintenance can cost your business money—and how predictive maintenance helps you detect issues early, reduce unnecessary repairs, and optimize equipment performance for long-term savings.

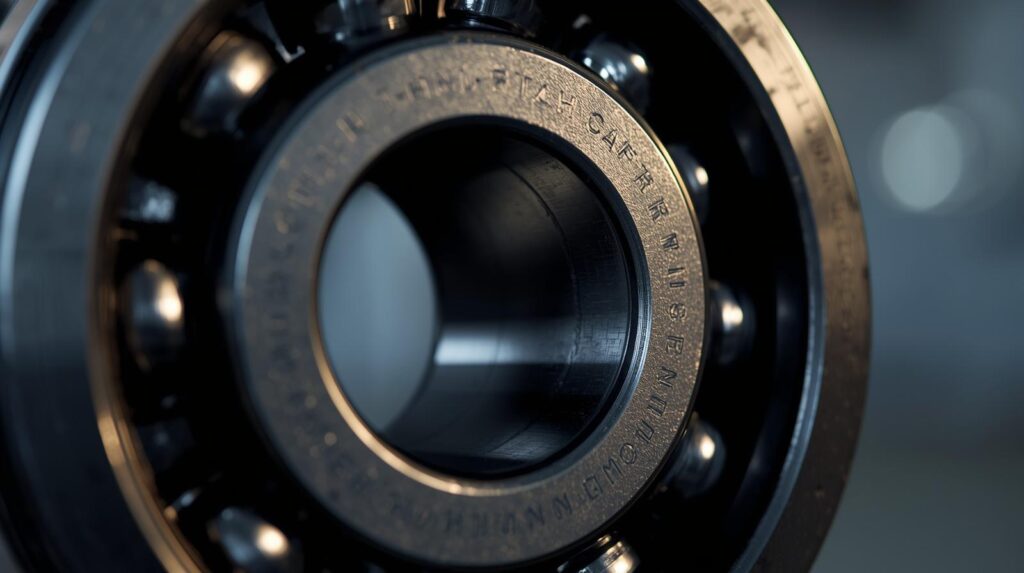

How to Stop Over-Greasing Bearings — and How Condition Monitoring Helps You Do It

In maintenance, more isn’t always better—especially when it comes to grease. Over-greasing bearings is one of the most common (and costly) mistakes in rotating equipment maintenance.

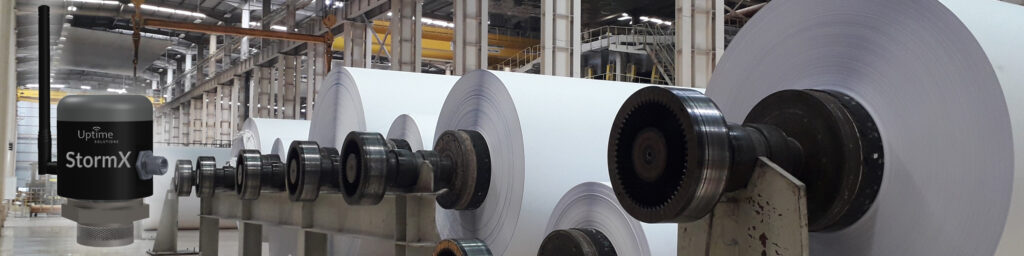

How to Reduce and Optimize Pump Rebuilds — and How Condition Monitoring Makes It Possible

Learn how to reduce pump rebuild frequency and costs using condition monitoring. See how real-time vibration, temperature, and ultrasound data drive reliability.

Condition Monitoring Secrets of High-Performing Plants

The best maintenance teams don’t guess — they know. See how condition monitoring gives reliability leaders the insight to predict failures, plan maintenance smarter, and eliminate costly downtime before it starts.

Why achieving uptime depends on people and processes — and then technology

As a reliability professionals, I can’t tell you how many times over my career I’ve visited customer sites and have been shown boxes full of sensors, sitting in the corner of the maintenance managers office gathering dust. There’s a different story behind each one of these boxes, but usually it has similar plot points:

Leveraging Accurate, Actionable Data for Condition Monitoring Success!

Our team recently returned from IR/INFO — the world’s premier infrared thermography conference. The hotel was buzzing with consultants, independent thermographers, and reliability engineers.

Are wireless ultrasonic sensors the future of condition monitoring for machine health?

In today’s fast-paced manufacturing landscape, where optimizing equipment performance and minimizing downtime are crucial for staying competitive, ultrasonic sensors have become a critical component of the ultrasound condition monitoring industry. As a result, this industry has emerged as a pivotal early-detection strategy for predictive maintenance.

Condition monitoring techniques

Since the dawn of industrialization, Condition Monitoring Techniques have evolved into an indispensable practice, performed at plants to safeguard the reliability and efficiency of industrial machinery, embracing technological advancements along the way. The methods used changed from visual and qualitative inspections to using hand-held devices to quantify the data — to today, where technology is available to monitor the condition of an asset anywhere in the world on a smartphone.

Wireless triaxial vibration sensors benefits – all those points in one for what?

Triaxial wireless vibration monitoring sensors give you three vibration monitoring sensors in one. One sensor provides you with Horizontal, Vertical, and Axial position readings, and there is no need for cables. Sounds great! But why would you need this? What are the benefits to using wireless triaxial vibration sensors for vibration diagnostics?

8 facts to reducing spoilage with condition monitoring

The food and beverage industry is especially vulnerable to complications when critical assets experience unplanned downtime in production facilities. It’s true. For example if an asset like an exhaust fan fails during a baking operation the temperature of the food product might not be maintained properly. This could result in waste due to losing the whole batch of product and the cost of the failure is compounded by the additional downtime to repair the disabled fan. Fortunately, monitoring machinery health (condition monitoring) can help to reduce spoilage and increase overall efficiency.